Complete Dry Room & Equipment

Bry-Air’s dehumidification systems and dry room equipment are engineered and manufactured to consistently provide reliable, complete solutions for moisture removal challenges on nearly every continent. Our company has a wide range of standard products; Bry-Air is distinguished by its unique ability to custom design and manufacture a system to optimally solve a specific customer problem.

Learn more about our dehumidification products and dry room equipment below.

A Bry-Air® Desiccant Cassette is the ideal solution for manufacturers of custom built air handling units in need of reliable humidity control.

Cassette Feature Highlights

Standard Features

- Easy to remove desiccant rotor

- Electric, steam, or direct or indirect fired gas reactivation

- Cleanable or disposable 30% inlet air filters

- Relay based controls for simple reliable operation

Optional Features

- Reactivation steam piping

- Purge section for ultra low dew point applications

- Programmable logic controls

- Allen Bradley

- Siemens

- Automation Direct

- As Requested

- Variable frequency drives

- Custom configurations for tight spaces

- 200 or 400mm Desiccant Rotor

With thirteen standard rotor sizes and a wide variety of packaging options, the Bry-Air® Desiccant Cassette can be tailored to match the specific requirements of challenging applications. With the Bry-Air® Desiccant Cassette you will get:

- The latest technology

- Solid welded aluminum construction

- Thirteen standard sizes from 300 to 30,000 CFM of dehumidified air

- Low cost of ownership

- Easier maintenance

- Ultimate flexibility of application

- A machine built to last

Bry-Air, Inc’s EcoDry® series desiccant dehumidifiers utilize our microprocessor-based system to dynamically control the desiccant dehumidifier operating parameters, dramatically improving part-load energy efficiency. Savings of up to 45% are common in most applications. It’s an ideal dehumidification solution for facilities concerned with energy efficient systems offering reliable, precise, independent temperature and humidity control with dew points as low as -80°F.

Desiccant Dehumidifier Standard Features

- Electric, steam, direct or indirect fired gas reactivation

- Hinged access doors with air handler style handles for easy inspection, cleaning, and maintenance

- Easy to service desiccant rotor

- Cleanable or disposable 30% inlet air filters on process and reactivation airstreams

- Allen Bradley PLC based controls for simple reliable operation

- Chain driven desiccant rotor for a lifetime of reliable performance

- Desiccant rotor manufactured in an ISO Certified Facility

- Hinged filter access doors with quick release fasteners

- Variable frequency drives

- Circuit breakers (not fuses) for over-current protection

- UL 508A certified electrical panels

- 0.125″ thick aluminum welded cabinet specifically designed to prevent moisture infiltration and leakage

Optional Desiccant Dehumidifier Features

- Reactivation heat energy recovery modules to reduce reactivation energy consumption

- Pre and/or post/after cooling coils of various configurations and materials for use with all standard cooling solutions and refrigerants

- DX condensing units and chillers – split system or packaged skid mounted

- Pre-piped steam, hot water, cooling coil piping systems

- Pre and/or post/after heat – electric, gas, hot water, or steam

- Humidification – steam injection, atomizing, ultrasonic, or adiabatic/evaporative

- On board steam generation systems – electric, gas, or steam-to-steam

- Removable 3″ double-sloped stainless steel drain pan

- 65%, 85%, 95% efficiency and HEPA filters or any combination thereof

- External or internal bypass ducts

- Purge section for ultra low dew point applications

- Programmable logic controls by manufacturers such as Siemens, Automation Direct, Johnson Controls, or your preferred controls system

- Custom configurations to fit your needs

With thirteen standard sizes and a wide variety of packaging options, the EcoDry® Series of dehumidification units can be tailored to match the specific requirements of challenging applications. Whether designed as a stand-alone unit or a complete package system, the EcoDry® industrial desiccant dehumidifier will meet your exact requirements.

With the EcoDry® Series Industrial Desiccant Dehumidifiers you will get:

- The latest technologies available in the industry today

- Solid welded aluminum construction

- Thirteen standard sizes from 300 to 30,000 CFM of dehumidified air

- 100,000 CFM or more total system air via custom configurations

- Low cost of ownership

- Easy maintenance

- Welded construction with hinged access door design

- Ultimate flexibility of application

- Rugged construction suitable for portable applications

- A unit capable of delivering air to -80°F dew point

- Proven reliability and performance

- A machine built to last

- Available extended warranties

- Preventive maintenance programs

- Annual inspect and tune programs

- 24/7 technical support

At Bry-Air, we realize that some industrial desiccant dehumidification specifications require a truly custom creation. We specialize in unique and custom creations for even the most demanding custom application. Our standard products are only the beginning of what Bry-Air offers to our customers. If you want clean sheet of paper design capability, we have the paper and the experience to meet your needs.

Bry-Air has been designing and building complete dehumidification package units since 1964. Put Bry-Air’s experience to work for you and experience the Bry-Air difference today.

- Colleges & universities

- Libraries

- Restaurants

- Government facilities

- Control rooms

- R&D, QC and bio med labs

- Critical materials store rooms

- Museums and conservatories

- Fine homes

- Clean rooms

- Retrofit existing systems for mold control

- High Efficiency and Reliability

- ETL listed

- A totally self-contained unit

- Insulated Process and Reactivation air flow sectors

- Rotor with stainless steel flange

- Differential air pressure switch for proving react air flow

- High temp safety thermostat

- Reactivation cool down

- Electrical interlock of fan motors, heaters and rotor drive

- Optional Humidistat for humidity control

- Suitable for continuous operation

- Auto / Manual selector switch

- Power on, heater on, and fault status indication

- Independent blower for each air stream

- Volume control dampers

- Several mounting and installation options

- Small physical size

- Easy to maintain

- Quick and easy to service

- Rotor is water washable

- A Compact dehumidification unit that fits easily into small places

- No replacement filters to inventory

- Half the energy consumption of over-cooling and reheat

- Low operating cost

- Quiet operation and the guaranteed performance of Bry-Air desiccant rotors

- Convert existing heating and cooling systems to maintain humidity control throughout the entire building (not just one room)

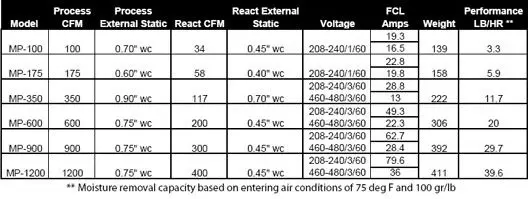

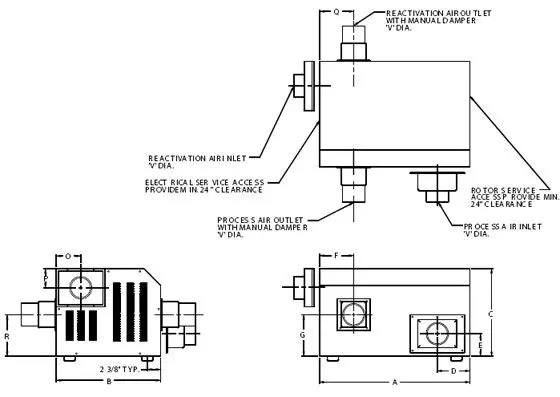

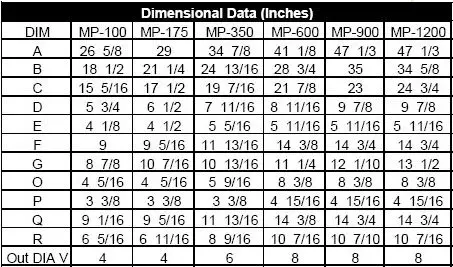

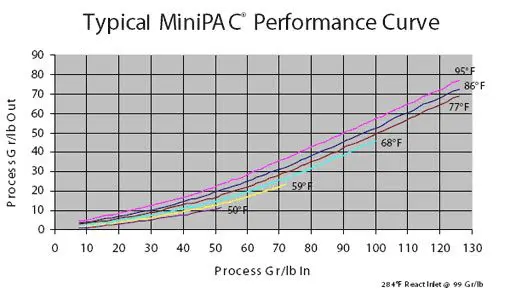

- Available in six CFM sizes: 100, 175, 350, 600, 900,1200, and 1800 CFM

- Optional pre and post cooling

- 24/7 tech support

- Quick ship options from our MiniPAC® inventory (Same day shipping available if processed before 12pm)

MiniPAC® Unit Details

Bry-Air, Inc’s VFB™ Industrial Dehumidifier is the ideal dehumidification solution for facilities in need of a reliable system for precise and independent temperature and humidity control with dew points as low as -80°F.

Standard Industrial Dehumidifier Features

- Electric, steam, direct or indirect fired gas reactivation

- Hinged access doors with air handler style handles for easy inspection, cleaning, and maintenance

- Easy to service desiccant rotor

- Cleanable or disposable 30% inlet air filters on process and reactivation airstreams

- Relay based controls for simple reliable operation

- Chain driven desiccant rotor for a lifetime of reliable performance

- Desiccant rotor manufactured in an ISO Certified Facility

- Hinged filter access doors with quick release fasteners

- Circuit breakers (not fuses) for over-current protection

- UL 508A certified electrical panels

- 0.125″ thick aluminum welded cabinet specifically designed to prevent moisture infiltration and leakage

Optional Industrial Dehumidifier Features

- Reactivation heat energy recovery modules to reduce reactivation energy consumption

- Pre and/or post/after cooling coils of various configurations and materials for use with all standard cooling solutions and refrigerants

- DX condensing units and chillers – split system or packaged skid mounted

- Pre-piped steam, hot water, cooling coil piping systems

- Pre and/or post/after heat – electric, gas, hot water, or steam

- Humidification – steam injection, atomizing, ultrasonic, or adiabatic/evaporative

- On board steam generation systems – electric, gas, or steam-to-steam

- Removable 3″ double-sloped stainless steel drain pan

- 65%, 85%, 95% efficiency and HEPA filters or any combination thereof

- External or internal bypass ducts

- Purge section for ultra low dew point applications

- Programmable logic controls by including our standard Allen Bradley or others such as Siemens, Automation Direct, Johnson Controls, or your specific brand preference

- Variable frequency drives

- Custom configurations to fit your needs

With thirteen standard sizes and a wide variety of packaging options, the VFB™-Series of industrial dehumidification units can be tailored to match the specific requirements of challenging applications. Whether designed as a stand-alone unit or a complete package system, the VFB™ industrial dehumidifier will meet your exact requirements.

With a VFB™-Series Industrial Dehumidifier you will get:

- The latest technologies available in the industry today

- Solid welded aluminum construction

- Thirteen standard sizes from 300 to 30,000 CFM of dehumidified air

- 100,000 CFM or more total system air via custom configurations

- Low cost of ownership

- Easy maintenance

- Welded construction with hinged access door design

- Ultimate flexibility of application

- Rugged construction suitable for portable applications

- A unit capable of delivering air to -80°F dew point

- Proven reliability and performance

- A machine built to last

- Available extended warranties

- Preventive maintenance programs

- Annual inspect and tune programs

- 24/7 technical support

At Bry-Air, we realize that some industrial dehumidification specifications require a truly custom creation. We specialize in unique and custom creations for even the most demanding custom application. Our standard products are only the beginning of what Bry-Air offers to our customers. If you want clean sheet of paper design capability, we have the paper and the experience to meet your needs.

Bry-Air has been designing and building complete dehumidification package units and dry room equipment since 1964. Put Bry-Air’s experience to work for you and experience the Bry-Air difference today.