ConAgra partnered with Bry-Air, Inc. to solve process environment issues at their plant in Jonesboro, Arkansas. The 80,000 sq. ft. plant provides deli-quality turkey products. The operational issues ConAgra and Bry-Air, Inc. agreed to address included:

- High humidity levels in the plant which caused continuous condensation issues.

- Severe negative pressures in the process areas.

- Process area temperatures that were near the limit of allowable specifications.

- Improper airflow patterns within the process area.

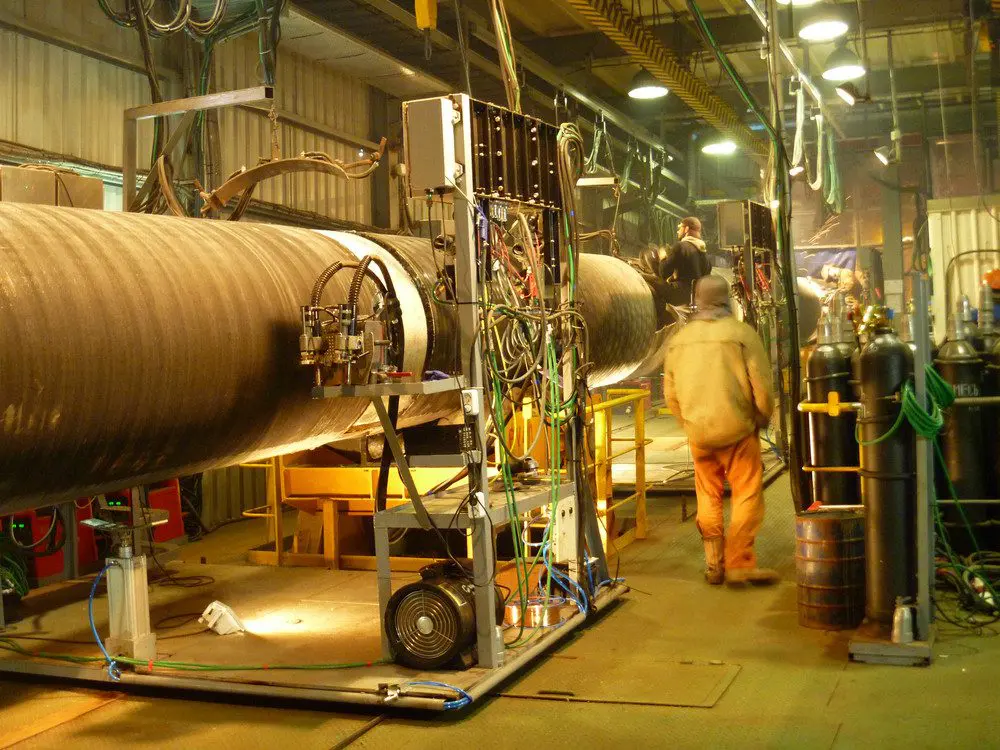

The first phase of the project involved an in-depth study of the plant processes and existing conditions. This included identifying all air systems, air flow patterns, current plant operation models, wash down and refrigeration system.From this in-depth analysis a plan was put together to address the issues. The plan included adding desiccant DH MUA systems, chillers, ductwork, utilities and modifying existing MUA systems, exhaust systems and air movement devices.The plan was implemented by ConAgra using purchased desiccant DH systems, rental chillers and local contractors for electrical, piping, duct work, roofing and rigging. Bry-Air, Inc. provided design, support, supervision, start-up and commissioning of the systems.The end results as follows:

- Humidity levels are being maintained well below condensation dew points at all ambient conditions.

- Process space temperatures have been lowered 5-10 degrees because of frost reduction on the refrigeration coils.

- Defrost cycles have been reduced by 50-70% and in some cases were completely eliminated.

- The process space is maintained with sufficient positive pressure to minimize or eliminate moisture and thermal infiltration

- Internal process space air flow patterns are correct for proper cleanliness and quality requirements.

- Wash-down dry-out is significantly quicker and less labor intensive.

- Process exhaust has been reduced by 60% with no negative effects on process quality.

- Floors dry quickly and stay dry during daily process cycle.

- Building structure has been dried out. Concrete is dry, roof structure is dry.

The Jonesboro facility’s problems were solved and all compliances were achieved.

To Download a PDF version of this case study click HERE.